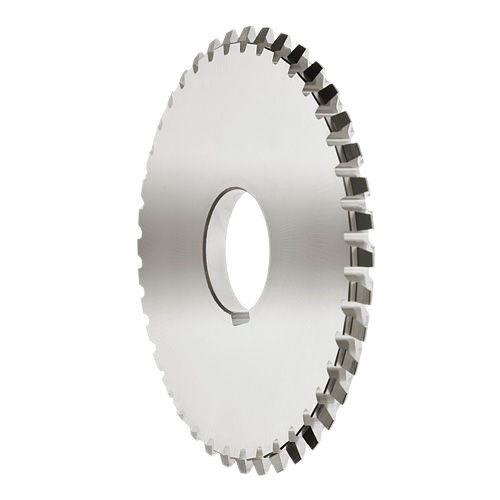

Solid Carbide Customized Tools are tailor-made cutting solutions designed to meet unique machining requirements that standard tools cannot fulfill. Manufactured entirely from solid carbide, these tools offer exceptional hardness, wear resistance, and dimensional accuracy, making them ideal for high-precision and high-volume machining.

-

Tailor-Made Design: Custom geometries, diameters, flute types, and coatings to suit specific machining requirements.

-

High Precision: Maintains tight tolerances and consistent dimensional accuracy.

-

Extended Tool Life: Premium solid carbide construction ensures superior wear resistance.

-

Versatile Applications: Suitable for milling, drilling, reaming, turning, and multi-operation processes.

-

High Productivity: Optimized for high-speed and high-feed machining with minimal downtime.

-

Cost-Effective: Reduces tooling inventory and improves operational efficiency

Solid Carbide Customized Tools are ideal for industries requiring high precision and specialized performance:

-

Automotive: Engine components, transmission parts, and precision molds

-

Aerospace: Aluminum alloys, composites, and titanium components

-

Tool & Die Making: Custom molds, dies, and precision engineering components

-

General Engineering: Machining of non-ferrous metals, hardened steels, and abrasive materials

When standard cutting tools cannot meet your machining requirements, Solid Carbide Customized Tools provide precision, durability, and efficiency. They are essential for manufacturers looking to achieve superior surface finish, reduced cycle times, and cost-effective machining.