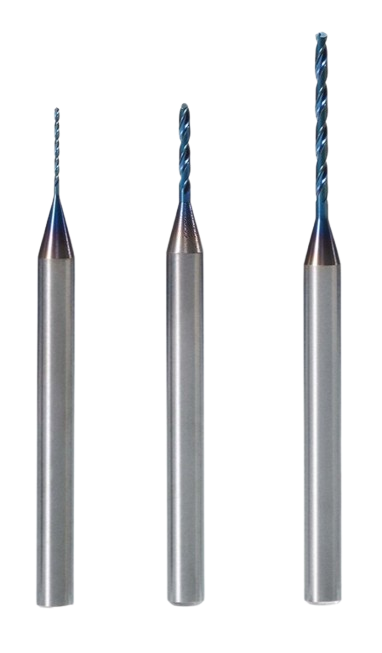

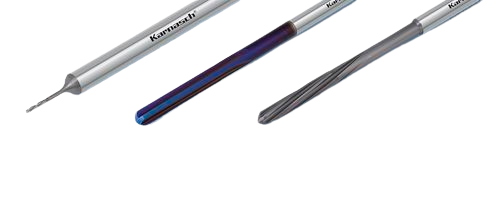

Solid Carbide Micro Drills are precision cutting tools designed for ultra-fine drilling in metals, alloys, and composite materials. Made entirely from solid carbide, these drills offer exceptional hardness, wear resistance, and dimensional stability, making them ideal for high-precision and high-speed applications.

They are widely used in industries that require small-diameter holes with excellent accuracy and surface finish, such as electronics, medical devices, and micro-mechanical components.

Quality Assurance

-

Dimensional Inspection & Verifying: We employ high-precision metrology (CMM, OGP, laser measurement) to certify each batch.

-

Tool Performance Testing: Select tools are tested under real application conditions to validate durability and repeatability.

-

Traceability & Documentation: Each tool carries a batch / serial number; inspection reports, certificates of conformity, and coating test data are provided upon request.

Why Choose VK Industries

-

Deep Expertise in micro-tooling and carbide tool manufacturing.

-

Customer-Centric Customization: We collaborate closely with your engineering teams to optimize tool design.

-

High Reliability: Our tools are built for demanding environments, ensuring consistency in high-volume production.

-

Technical Support & After-Sales Service: We offer application guidance, tool parameter optimization, and regrinding / refurbishment where feasible.

-

Competitive Lead Times: Despite the complexity of micro tooling, we strive to deliver within short lead times without compromising quality.