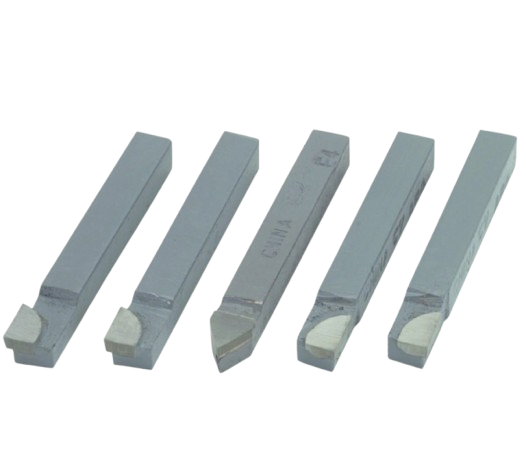

Carbide Lugged Tools are specialized cutting tools with carbide tips or inserts mounted on a lugged body, designed for heavy-duty machining and high-precision applications. The lugged design provides enhanced stability, reduced vibration, and better heat dissipation, ensuring long tool life and superior surface finish.

Applications

Carbide Lugged Tools are widely used in industries requiring high-precision and heavy-duty machining:

-

Automotive: Engine blocks, transmission parts, and structural components

-

Aerospace: Aluminum, titanium, and composite parts

-

Tool & Die Making: High-precision molds, dies, and components

-

General Engineering: Machining of metals, non-ferrous alloys, and abrasive materials

Available Options

-

Carbide Lugged Endmills

-

Carbide Lugged Drills and Reamers

-

Special Custom Designs for High-Performance Applications

Advantages of Choosing V K Industries Group

-

Extended Tool Life – Carbide tips and robust lugged design ensure durability in demanding environments.

-

High Accuracy & Repeatability – Manufactured to strict tolerances for precise machining.

-

Custom Solutions – Tools designed and produced according to your drawings, samples, or requirements.

-

Improved Productivity – Reduced vibration and tool deflection for faster, more efficient machining.

-

Reconditioning Services – Tip replacement and refurbishment extend tool life and reduce costs.