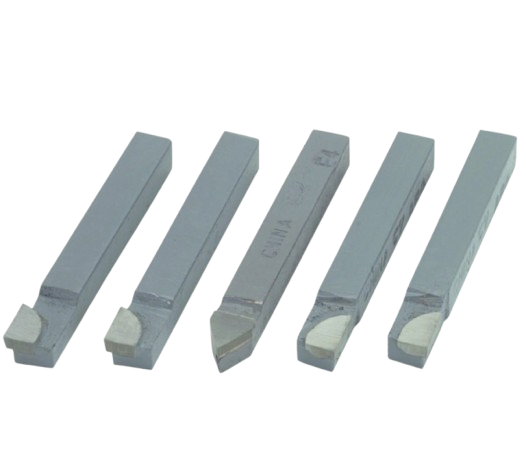

Carbide Tipped Tools are cutting tools in which high-performance carbide inserts are brazed or mechanically attached to a tool body, combining the strength of a steel body with the hardness and wear resistance of carbide tips. These tools are designed for precision machining, high-speed operations, and heavy-duty cutting, offering long tool life, consistent performance, and superior surface finish.

They are widely used in applications where tool replacement costs need to be minimized while maintaining high productivity and precision.

Carbide Tipped Tools are widely used in industries requiring precision and durability:

-

Automotive: Engine blocks, transmission parts, brake components

-

Aerospace: Aluminum alloys, composites, and structural components

-

Tool & Die Making: High-precision molds, dies, and machining components

-

General Engineering: Machining of metals, non-ferrous alloys, and abrasive materials