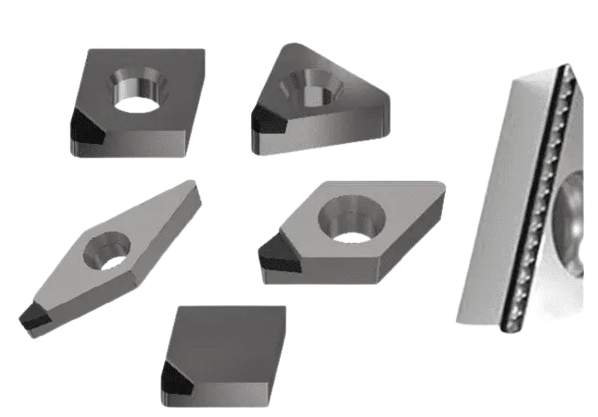

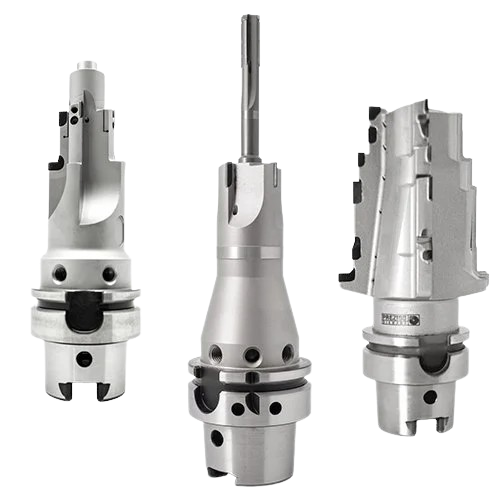

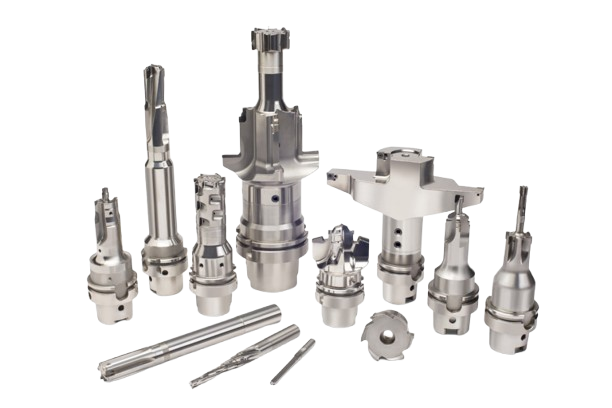

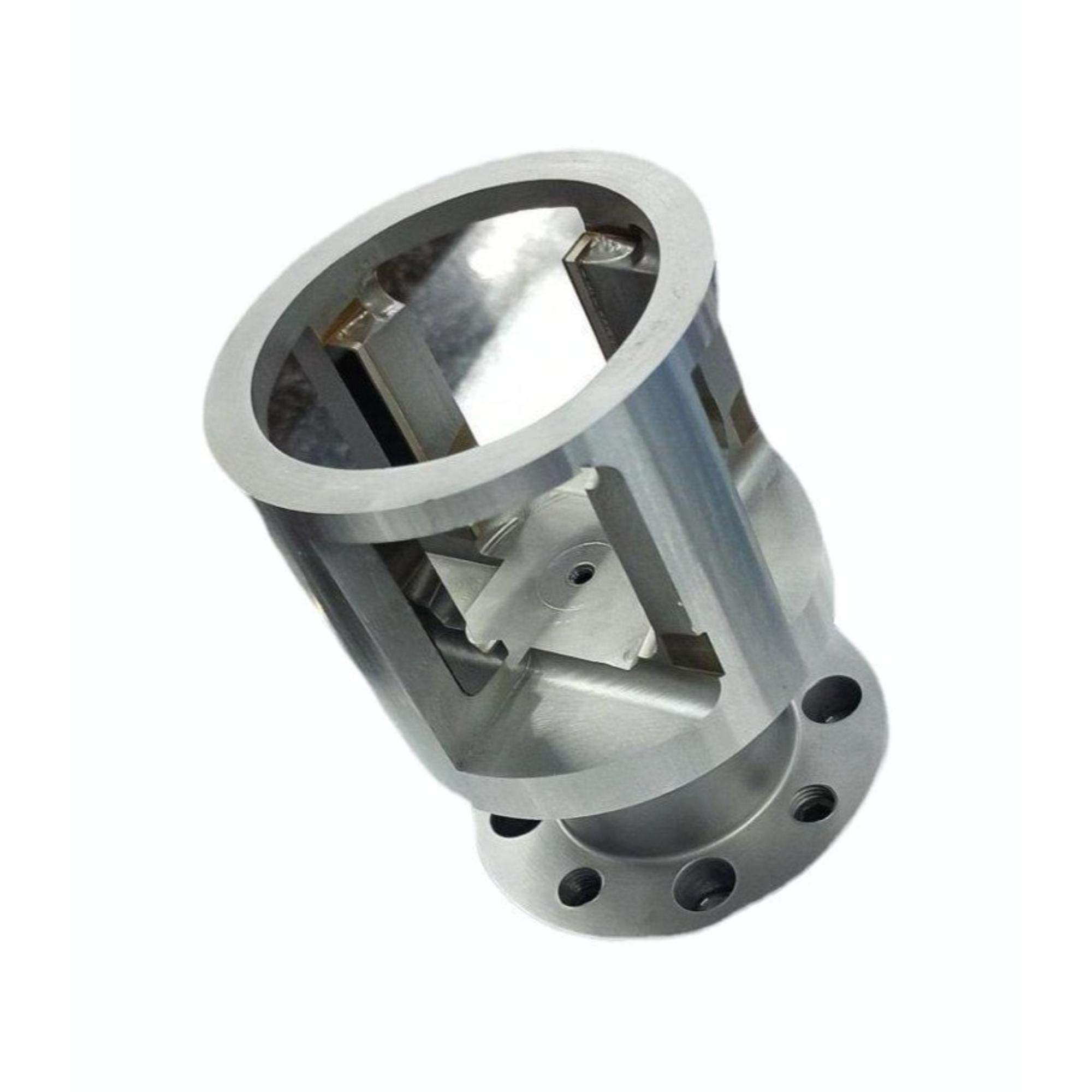

PCD Hole Mills are specialized cutting tools designed for the milling and finishing of precision holes in non-ferrous, abrasive, and composite materials. Unlike traditional drills or reamers, hole mills combine the accuracy of reaming with the flexibility of milling, ensuring excellent hole quality, tight tolerances, and superior surface finish.

Tipped with Polycrystalline Diamond (PCD), these tools deliver exceptional wear resistance, long tool life, and reliable performance in high-volume machining.

PCD Hole Mills are widely used in industries where precision and efficiency are critical:

-

Automotive: Precision bores in engine blocks, gear housings, and brake components

-

Aerospace: Lightweight alloys and composite materials machining

-

Hydraulics & Pumps: Accurate holes in valve bodies and pump housings

-

General Engineering: Non-ferrous materials like aluminum, brass, and copper

Advantages of Choosing V K Industries Group

-

Tailor-Made Solutions – Designed as per customer drawings, part geometry, and production requirements.

-

Micron-Level Accuracy – Manufactured to ±0.005 mm tolerance or better.

-

Cost Efficiency – Reduced tool changes, less downtime, and lower cost-per-component.

-

Reconditioning & Retipping – Maximize the lifecycle of your tools with our reconditioning services.