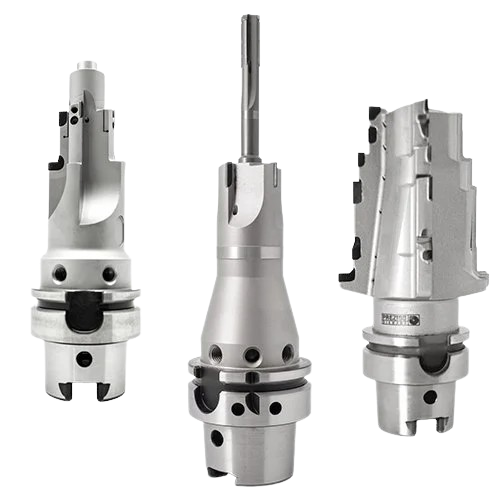

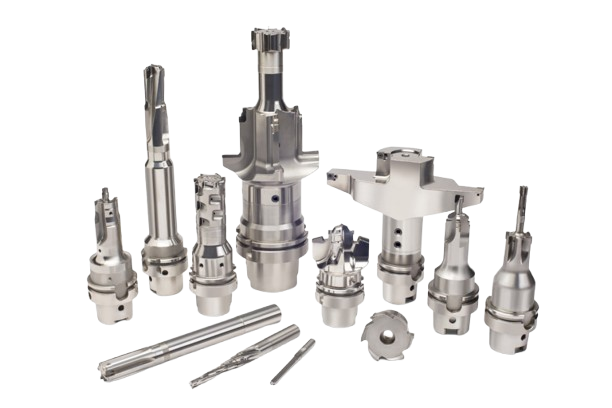

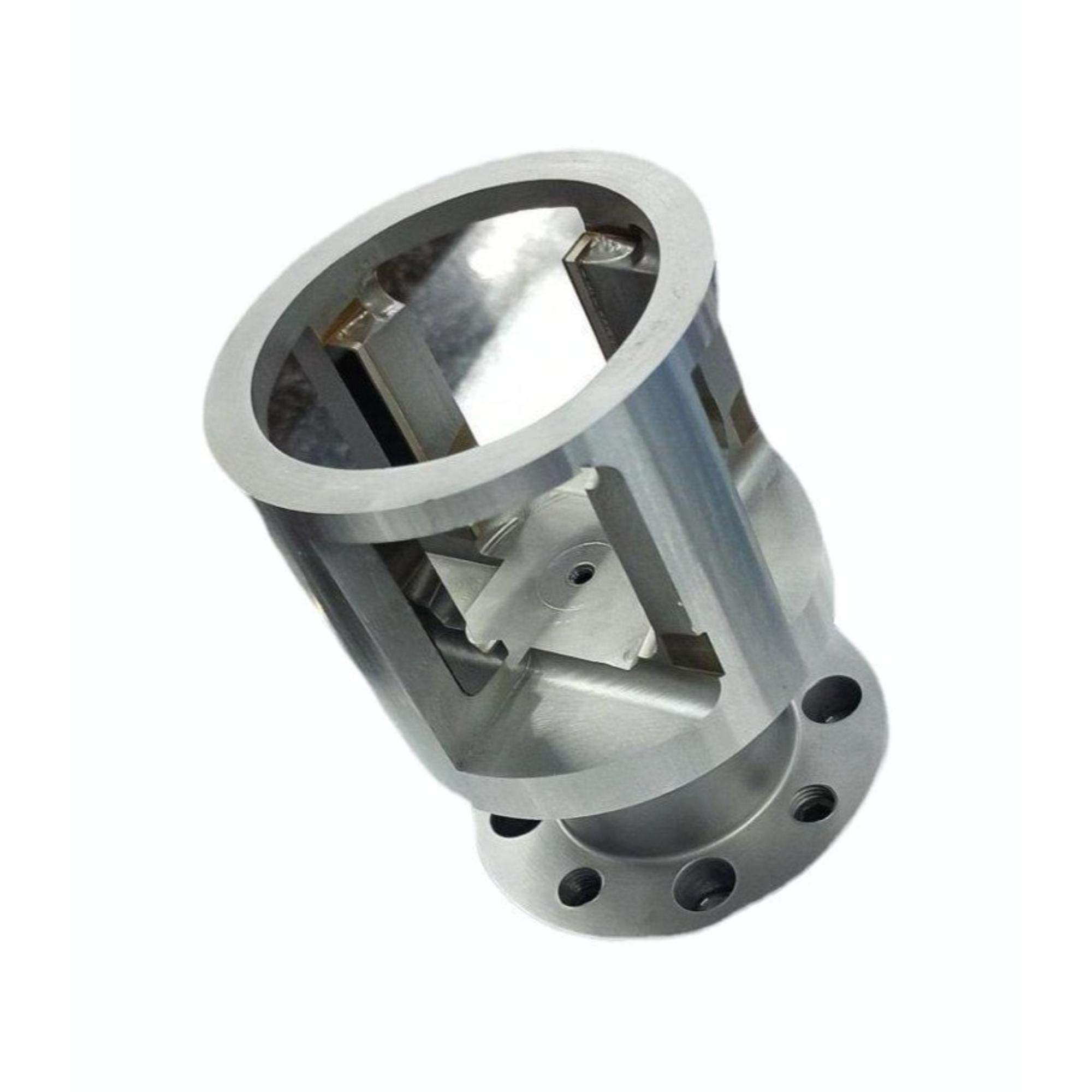

PCD Step Reamers are advanced precision tools designed to perform multiple reaming operations in a single pass. By integrating different diameters (steps) along one tool body, they allow manufacturers to achieve multi-diameter holes with perfect alignment, accuracy, and surface finish — all while reducing cycle time and tool changes.

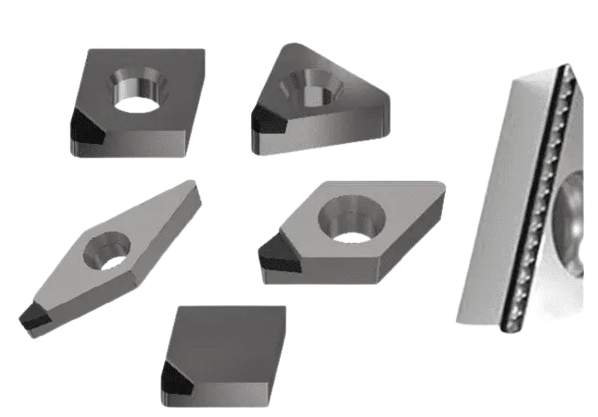

The cutting edges are tipped with Polycrystalline Diamond (PCD), ensuring maximum wear resistance, extended tool life, and consistent precision even in abrasive and high-volume machining environments.

Our PCD Step Reamers

-

Multi-Diameter Accuracy

Achieve concentric, precise bores with multiple diameters in a single operation. -

High Wear Resistance

PCD cutting edges ensure outstanding durability when machining abrasive or composite materials. -

Improved Productivity

Minimize tool changes and reduce machining cycle time by combining steps in one tool. -

Superior Surface Finish

Consistent hole quality with minimal chatter, burrs, or deviations. -

Customizable Designs

Step configurations, diameters, flute geometry, and coolant channels are tailored to your application.

Benefits of Choosing V K Industries Group

-

Precision Manufacturing: Reamers produced with micron-level tolerances.

-

Engineering Support: Custom tool design based on your part drawing or specification.

-

Extended Tool Life: Reduced downtime and cost per component due to fewer replacements.

-

Reconditioning Services: Retipping and refurbishment to maximize tool investment.