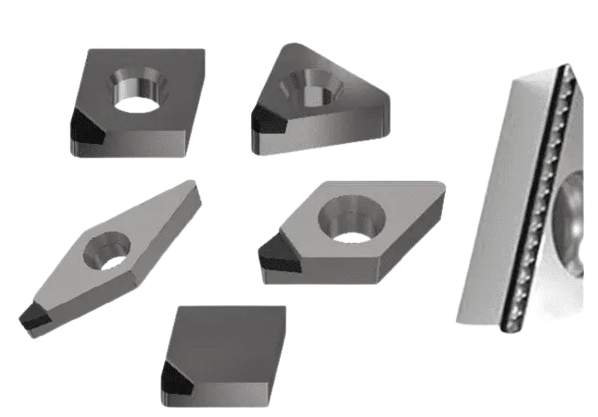

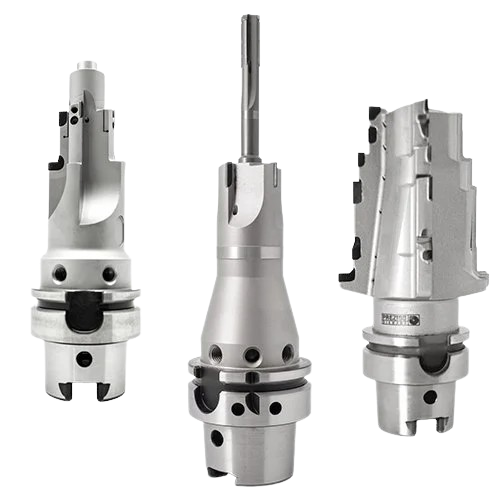

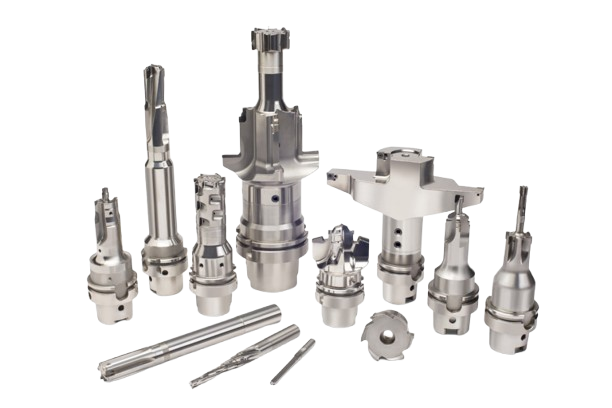

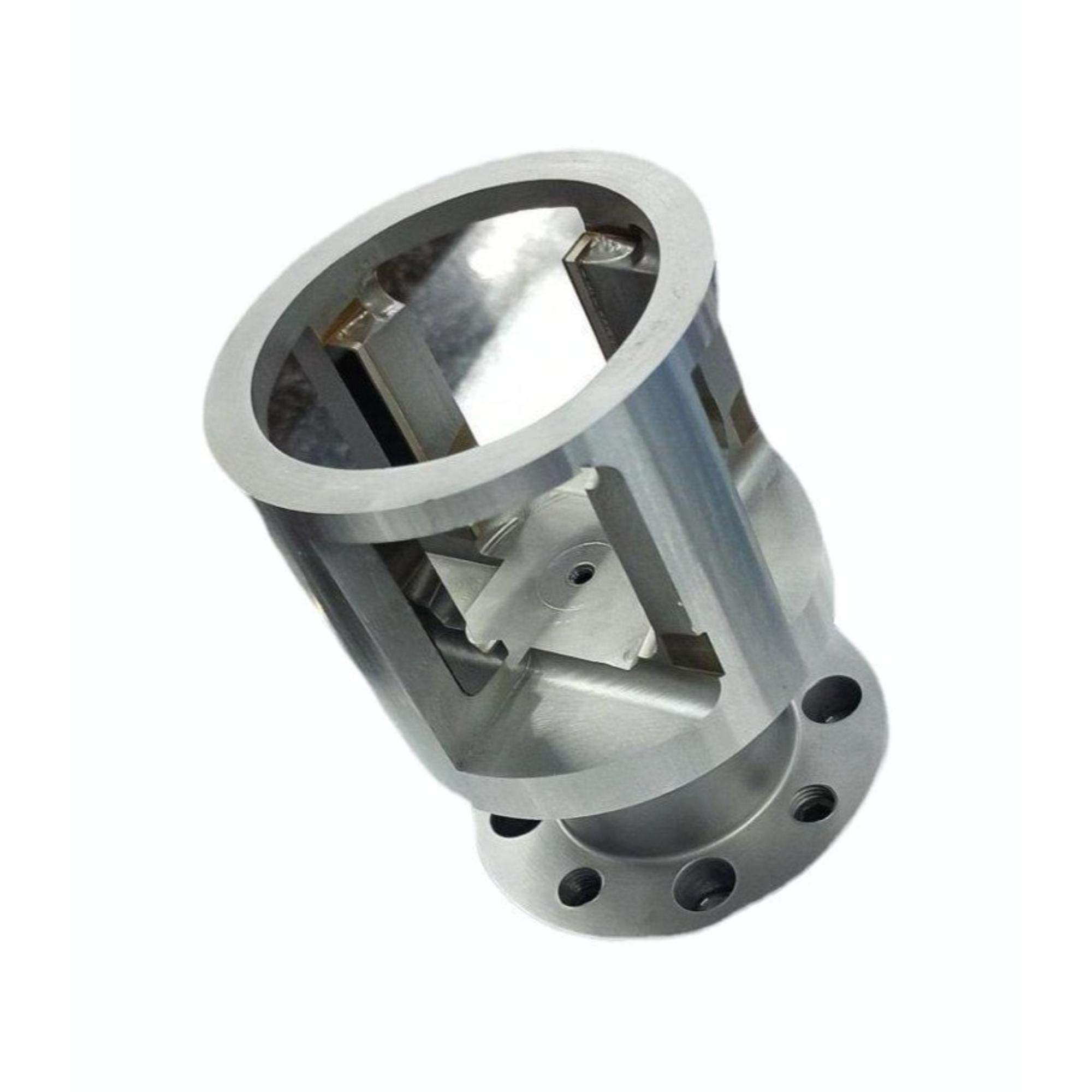

SPL PCD Tools (Special PCD Tools) are custom-engineered cutting solutions designed to meet unique machining challenges that standard tools cannot solve. Manufactured with Polycrystalline Diamond (PCD) cutting edges, these tools deliver superior wear resistance, longer tool life, and unmatched precision when machining non-ferrous alloys, composites, and abrasive materials.

They are developed specifically for customer applications, ensuring maximum productivity, reduced cycle time, and consistent part quality.

Our SPL PCD Tools are widely used in:

-

Automotive – Cylinder heads, valve guides, aluminum engine parts, and transmission housings

-

Aerospace – Lightweight alloys, CFRP panels, and composite assemblies

-

Electronics – Precision machining of copper, brass, and plastics

-

Oil & Gas – Large bore machining in heavy-duty components

-

General Engineering – Special-purpose machining where standard tools are not effective

Why Choose V K Industries Group for SPL PCD Tools?

-

-

Complete Customization – We design tools to your exact requirements, drawings, or samples.

-

Expert Engineering Support – Our team helps optimize tool geometry for maximum efficiency.

-

Proven Quality – Manufactured with advanced technology and strict quality control.

-

Reconditioning Services – Retipping and refurbishment extend the lifespan of your tools.

-

Cost-Effective Solutions – Save time, reduce downtime, and lower your cost per component.

-