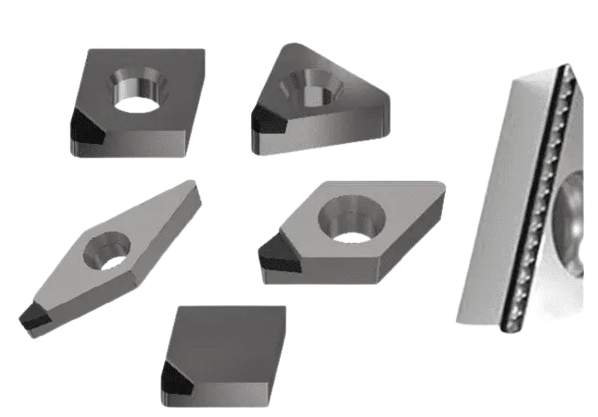

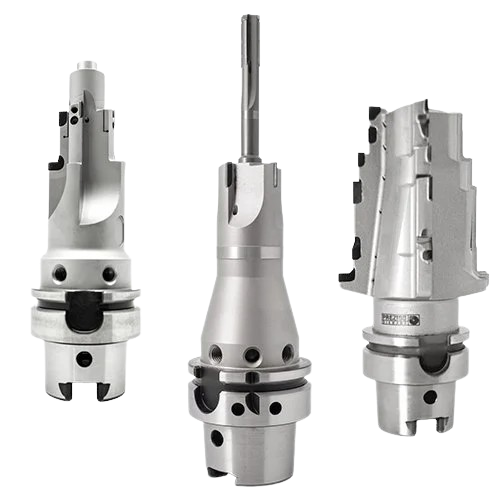

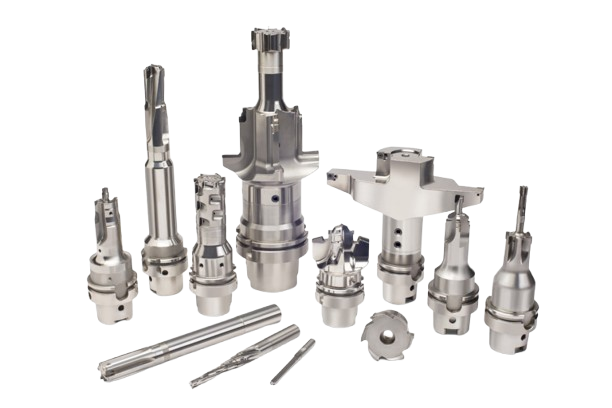

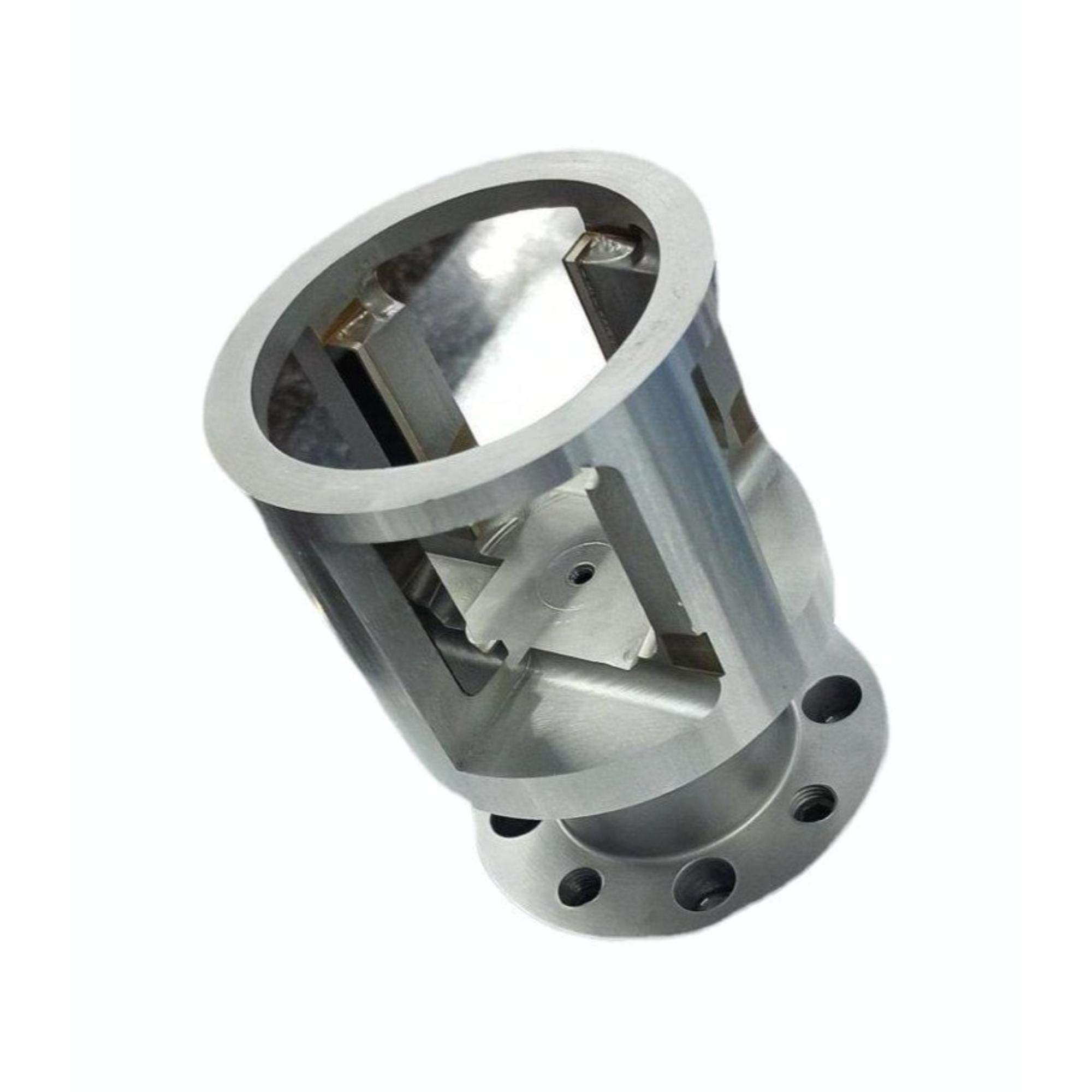

PCD (Polycrystalline Diamond) and PCBN (Polycrystalline Cubic Boron Nitride) Inserts & Bites are high-precision cutting components used in turning, grooving, milling, and boring operations. These inserts are designed to deliver exceptional hardness, wear resistance, and surface finish, making them ideal for machining abrasive, hard, and high-strength materials.

-

PCD Inserts are optimized for non-ferrous metals, composites, and plastics.

-

PCBN Inserts are ideal for hard ferrous alloys, hardened steels, and cast irons.

PCD / PCBN Inserts & Bits are widely used in:

-

Automotive: Engine blocks, transmission components, and brake parts

-

Aerospace: Structural components in aluminum, composites, and other hard-to-machine materials

-

Tool & Die Making: Precision grooves, profiles, and finishing operations

-

General Engineering: High-accuracy machining of non-ferrous and hardened materials

For precision manufacturing where hardness, wear resistance, and surface quality are critical, PCD and PCBN inserts offer unmatched performance. They ensure long-lasting tool life, reduced downtime, and high-quality finished components across automotive, aerospace, general engineering, and composite machining applications.