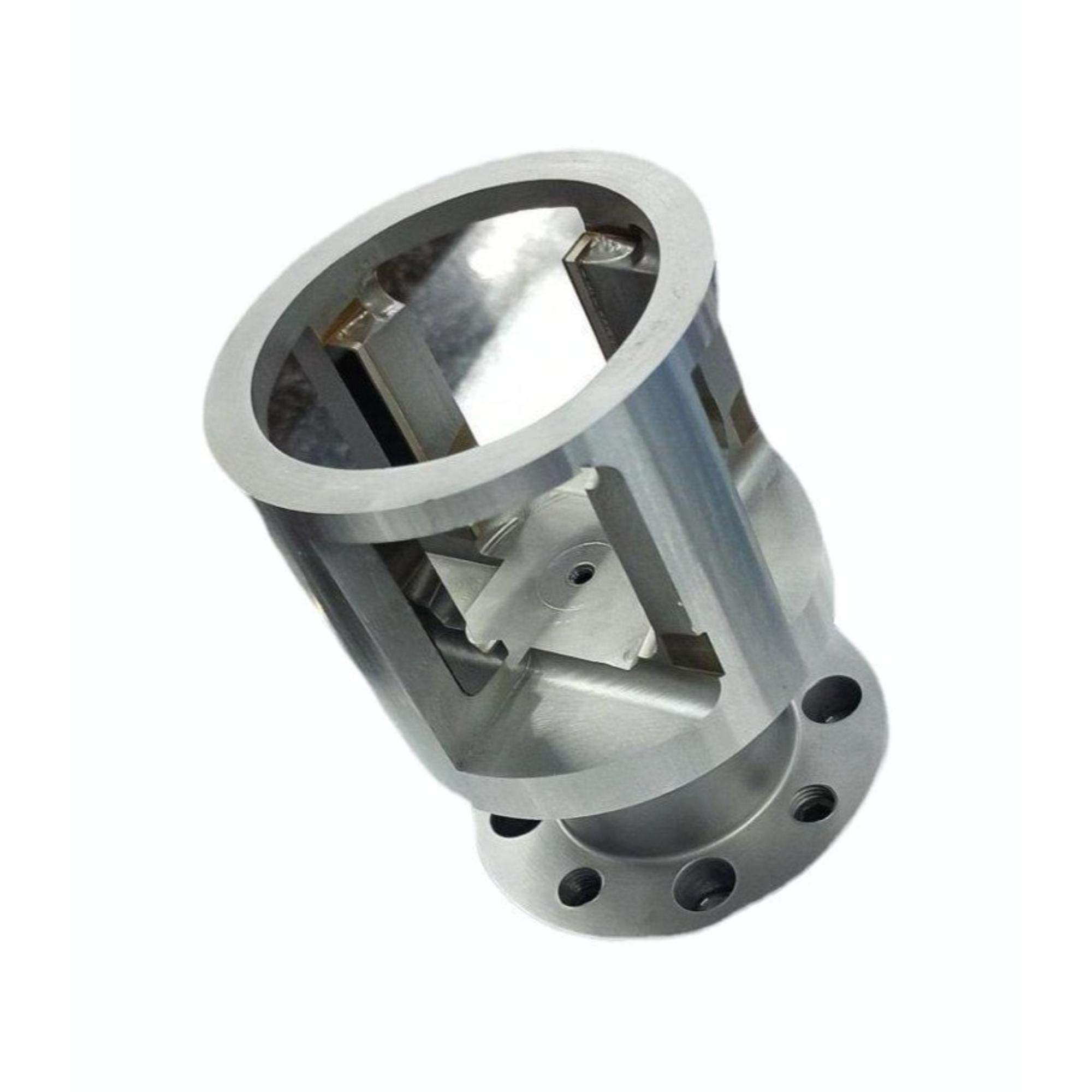

PCD (Polycrystalline Diamond) reamers are precision cutting tools designed for finishing and sizing holes in hard, abrasive, or composite materials. The PCD cutting edges provide superior wear resistance, long tool life, and excellent surface finish, making them ideal for high-volume and high-precision machining applications.

Our Offering

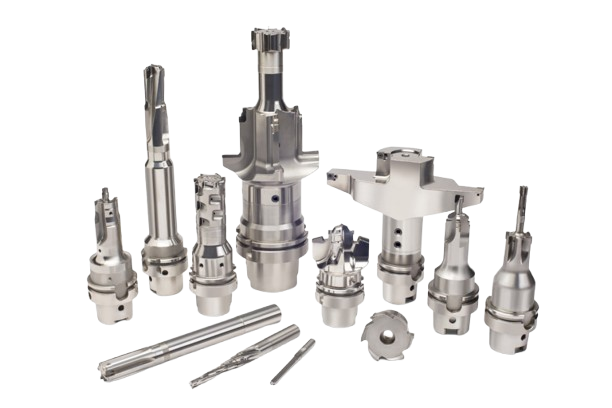

At V K Industries Group, we specialize in designing, manufacturing, and supplying high-quality PCD Reamers tailored to exacting specifications. Our solutions cater to a wide variety of industries, including automotive, aerospace, composites, rail, and general engineering.

Key Product Features

-

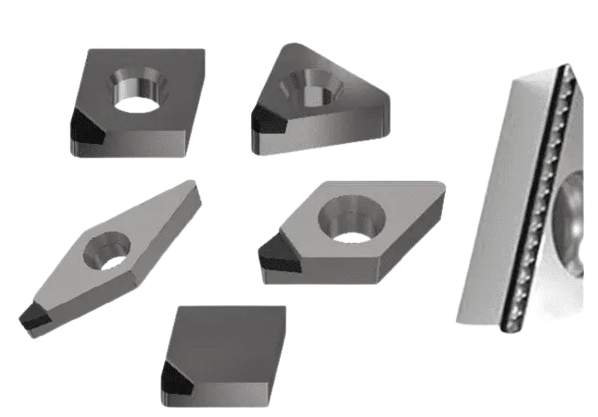

Premium PCD Cutting Tips

Our reamers incorporate PCD inserts of the highest grade, ensuring long-lasting cutting edges, minimum tool wear, and consistent performance even in demanding conditions. -

Precision and Tolerance

We manufacture reamers to tight tolerances (e.g. ± 0.005 mm or better) to ensure that your bore finish and dimensional accuracy meet stringent standards. -

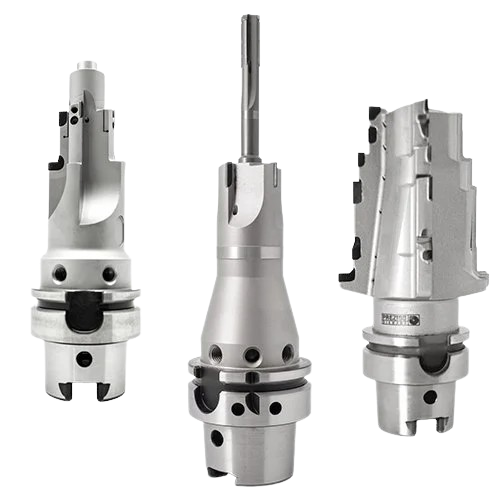

Custom Designs & Sizes

Whether standard reamer diameters or highly customized sizes, we can deliver based on the drawing, sample, or specification you provide. -

Optimized Geometry

Flute designs, helix angles, margin widths, and coolant channels are optimized for chip evacuation, surface finish, and minimal cutting forces. -

Coatings & Treatments

We offer surface coatings (e.g. TiN, TiAlN) or special treatments to enhance performance in difficult machining conditions or reduce friction and friction-induced heat. -

Enhanced Tool Life & Cost Efficiency

The durability of PCD tips leads to fewer tool changes, lower downtime, and better overall operational efficiency.